MEDIUM PRESSURE WITH BACKWARD IMPELLER

MANUFACTURING FEATURES:

• Fan made of Fe360 sheet. The fan paint finish is based on a Qualicoat polyester powder coating stoved at 200ºC, with an average film thickness of 70 microns. Average heat resistence of coating is 180ºC with peaks of 200ºC.

• Fully welded or joined housing.

• Simple inlet backward impeller with self-cleaning system made of Fe360 sheet statically and dynamically balanced.

Impellers are painted with polyester primer that resists temperatures up to 300ºC.

• Standard asynchronous squirrel-cage motor with IP-55 protection and class F insulation. Manufactured with standard voltages: 230/400V 50Hz in single phase motors and 230/400V 50Hz in three phase motors up to 4kW and 400/690V 50Hz for higher powers.

• Standard orientation LG270.

• It allows adjusting the orientation locally from models 250 to 630. Models sizes from 710 to 1400 size the orientation is fixed.

APPLICATIONS:

Designed for inline installation, they are suitable for:

• Industrial applications, extraction or injection of air.

• Cooling of machines and parts.

• Clean and slightly dusty air transport.

• Exhaust after filters, separators and cyclones.

• Pneumatic transport.

• Maximum working temperature: carried air: 130ºC, ambient: 60ºC.

UNDER REQUEST:

• 60Hz fans and special voltages.

• 2 speed motors.

• Spark-proof fans with ATEX certified motor.

• Fan for air working temperatures up to 250ºC with R/R (cooling impeller).

• Hot-dipped galvanised or stainless steel fans.

• Orientation: RD0, RD45, RD90, RD135, RD180, RD225, RD270, RD315, LG0, LG45, LG90, LG135, LG180. LG225, LG315.

| A | a | a1 | a2 | B | b | b1 | b2 | C | D | d | d1 | D1 | d2 | D2 | D3 | D4 | D5 | D6 | D7 | E | F | G | H | H1 | H2 | I | J | K | M | N1xØ1 | n1xp | N2xØ2 | n2xp | O6 | Ø3 | Q | R | S | S1 | S2 | S3 | S4 | S5 | S6 | S7 | X | X1 | X2 | X3 | X4 | X5 | X6 | X7 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 117 | 322 | 366 | 402 | 452 | 229 | 273 | 309 | 557 | 225 | 320 | 366 | 397 | 400 | 316 | 332 | 288 | 256 | 253 | 440 | 656 | 196 | 117 | 400 | 225 | 400 | 86 | 184 | 206 | 145 | 8x12 | 1x125 | 10x12 | 2x125 | 215 | 10 | 45 | 14 | 332 | 256 | 253 | 225 | 440 | 397 | 316 | 288 | 256 | 255 | 440 | 397 | 316 | 332 | 288 | 253 |

MANUFACTURING FEATURES

• Safety start-stop switches according to IEC 60947-1 and IEC 60947-3.

• IP65 and always equipped an auxiliary contact.

• Useful for switching off the current before handling the fan.

*Máx. thermal current air (A)

MANUFACTURING FEATURES

• Flexible joint to clinch the fan to the duct.

• Avoids transmission of vibrations for circular and rectangular connection.

• Dimensions: two metallic flanges of 45mm each one and a flexible flange of 60mm.

• The reel is 30,5m lenght.

• Maximum pressure: 20 mmca.

• Fire resistance M0 from -50ºC to +200ºC in continuous and 400ºC/2h.

MANUFACTURING FRATURES

• Inlet protection guard to avoid the entry of objects and contact with the impeller.

• Made of galvanised steel models 7,9, 10, 12 and 15. And the rest of models with polyester powder finishing coat.

MANUFACTURING FRATURES

• Galvanized protection grid on the outlet side to avoid the entry of objects and contact with the impeller.

MANUFACTURING FEATURES

• Connection to be fitted in the centrifugal fans outlet.

• Manufactured in galvanized steel.

UNDER REQUEST

• Versions in stainless 304 and stainless 316.

MANUFACTURING FEATURES

• Specially designed for speed frequency control in ventilation applications.

• Ultra compact, simple operation and wide range of functions.

*Dial panel incorporated. Optional EMC filter.

Certifications: CE/UL/CSA/EN/GOST/CCC.

Protection index IP20.

The selection of SFC frequency drive speed controller must be made based on the maximum intensity absorbed by the fan to be regulated. The powers (kW) and the intensity for constant load refer to the normal duty (150% overload for 60 seconds). The intensity for quadratic load admits an overload of 110% during 60s.

SFC 230: Entrance 230V I, exit 230V III

SFC 400: Entrance 400V III, exit 400V III

EMC filter incorporated for models from 47A (included)

*Lineal load rated current

**Quadratic load rated current

MANUFACTURING FEATURES

• Specially designed for speed frequency control in ventilation applications.

• Ultra compact, simple operation and wide range of functions.

*Dial panel incorporated. Optional EMC filter.

Certifications: CE/UL/CSA/EN/GOST/CCC.

Protection index IP20.

The selection of SFC frequency drive speed controller must be made based on the maximum intensity absorbed by the fan to be regulated. The powers (kW) and the intensity for constant load refer to the normal duty (150% overload for 60 seconds). The intensity for quadratic load admits an overload of 110% during 60s.

SFC 230: Entrance 230V I, exit 230V III

SFC 400: Entrance 400V III, exit 400V III

EMC filter incorporated for models from 47A (included)

*Lineal load rated current

**Quadratic load rated current

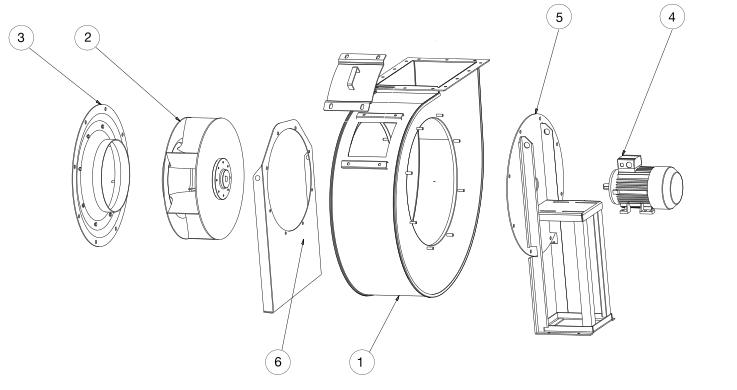

| Nº | Code | Family | Name | Qty |

|---|---|---|---|---|

| 2 | T01603140 | TURBINE | MBRL 312 T4 0,18kW LG | x1 |

| 3 | 503403100SP04 | INLET CONE | MBRL/MTRL 310 | x1 |

| 4 | 721001119 | MOTOR | 0,18kW T4 B3 230/400V | x1 |