SMOKE EXTRACTION BACKWARD CASING FAN 400ºC/2h

MANUFACTURING FEATURES

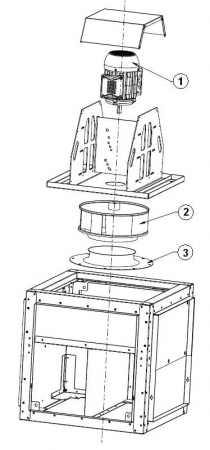

CASING:

• Made of galvanized steel sheet with connection flanges and inspection door.

• Changeable panels.

MOTOR SUPPORT:

• Galvanised steel plate, motor with flanges fixed on 2 supports. Removable plate / support / impeller set.

IMPELLER:

• Backward centrifugal impeller, made of galvanised steel, dynamically balanced and sel-cleaning.

• Direct drive on the motor shaft.

MOTOR:

- Three phase motor with IP-55 protection and F class insulation. Manufactured with standard voltages for one speed motors:

230/400V 50Hz up to 4 Kw and 400/690V 50Hz for higher powers of 4 and 6 poles.

2 speed motors:Dahlander 400V 50Hz

APPLICATIONS

• Smoke extraction in high buildings and establishments with people.

• Ventilation and smoke exhaust in covered parkings.

• Ventilation in technical, industrial or commercial facilities.

• Maximum continuous working temperature: carried air 110ºC, environment 60ºC.

Official homologation by the European laboratory APPLUS according to EN 12101-3:2015

Certification Nr: 0370-CPR-2681

| A | B | C | D | E | H | I | K | L | L1 | L2 |

|---|---|---|---|---|---|---|---|---|---|---|

| 600 | 600 | 600 | 912 | 312 | 278 | 161 | 26 | 495,7 | 181,1 | 313,1 |

MANUFACTURING FEATURES

• Safety start-stop switches according to IEC 60947-1 and IEC 60947-3.

• IP65 and always equipped an auxiliary contact.

• Useful for switching off the current before handling the fan.

*Máx. thermal current air (A)

Safety switch for local disconnection of 400ºC/2h ventilation equipments according to UNE-EN 12101-3.

Suited for direct control of motor in AC 3 operation category

Equips two auxiliary contact.

MANUFACTURING FEATURES

• Connection flange for rectangular outlet of DHUMAT, to make the connection to a circular duct easier.

• Made of galvanized steel.

MANUFACTURING FEATURES

• Support made of galvanized steel.

MANUFACTURING FEATURES

• Outdoor flange with bird guard for DHUMAT.

• Made of galvanized Steel.

MANUFACTURING FEATURES

• Specially designed for speed frequency control in ventilation applications.

• Ultra compact, simple operation and wide range of functions.

*Dial panel incorporated. Optional EMC filter.

Certifications: CE/UL/CSA/EN/GOST/CCC.

Protection index IP20.

The selection of SFC frequency drive speed controller must be made based on the maximum intensity absorbed by the fan to be regulated. The powers (kW) and the intensity for constant load refer to the normal duty (150% overload for 60 seconds). The intensity for quadratic load admits an overload of 110% during 60s.

SFC 230: Entrance 230V I, exit 230V III

SFC 400: Entrance 400V III, exit 400V III

EMC filter incorporated for models from 47A (included)

*Lineal load rated current

**Quadratic load rated current

MANUFACTURING FEATURES

• Specially designed for speed frequency control in ventilation applications.

• Ultra compact, simple operation and wide range of functions.

*Dial panel incorporated. Optional EMC filter.

Certifications: CE/UL/CSA/EN/GOST/CCC.

Protection index IP20.

The selection of SFC frequency drive speed controller must be made based on the maximum intensity absorbed by the fan to be regulated. The powers (kW) and the intensity for constant load refer to the normal duty (150% overload for 60 seconds). The intensity for quadratic load admits an overload of 110% during 60s.

SFC 230: Entrance 230V I, exit 230V III

SFC 400: Entrance 400V III, exit 400V III

EMC filter incorporated for models from 47A (included)

*Lineal load rated current

**Quadratic load rated current

MANUFACTURING FEATURES

• Support of great radial and axial elasticity.

• These low-profile, compact and elastic supports control the three directions of movement with large deformations in the rubber.

• It consists of two parallel armour adhered to the bell-shaped rubber and by a base with handles.

• These supports with handles have a threaded hole in their upper frame and are easy to install and fix.

• The steel protection washer allows it to withstand overloads by increasing its rigidity and protects the rubber from dripping hydrocarbons.

• Elastomer type NR or high quality elastomer. Working temperatures between -40ºC and + 70º C.

• Taking into account the tolerances of hardness in the elastomers, the mechanical characteristics of these series may differ.

• Range of 6 sizes and 3 different hardnesses (45-60-75) to fit a load range between 2 Kg and 1300 Kg.

1. Soft: hardness A 45

2. Average: hardness B 60

3. Hard: hardness C 75

APPLICATIONS

• Very appropriate in the elastic suspensions of machines that present vibrations of horizontal components.

MANUFACTURING FEATURES

• Metal insulators designed to work with compression with 85% insulation according to the following arrows (travel in mm) and rpm:

Arrow (mm.) r.p.m.

20 mm >600 r.p.m.

30 mm >500 r.p.m.

• Made of high quality elastic steel, with rectangular base and rubber mat to improve the grip. It treats of a resistant product and easy assembly, that avoids all type of vibrations of the fans to the structure of the premises.

• Operating temperature from -45 ° C to + 120 ° C.

APPLICATION

• To install under machines with rotating components, ventilation groups, fans, ventilation boxes, etc.

| Nº | Code | Family | Name | Qty |

|---|---|---|---|---|

| 1 | 721001053 | MOTOR | 2,2kW T2 B3 230/400V | x1 |

| 2 | R-245359381 | TURBINE | DHUMAT 355-1 D24 LG | x1 |

| 3 | R-279351680 | INLET CONE | ED11 355 | x1 |